Silicone-free Butchery

Every producer of high-quality meat and sausage products has his own production focus, his own ideas and concepts for his new production facility. That’s why Schwan Projekt always coordinates the operating procedures in cooperation with the respective building owner. In addition, possible subsidies from the federal government, federal states and EU funding pots must be checked.

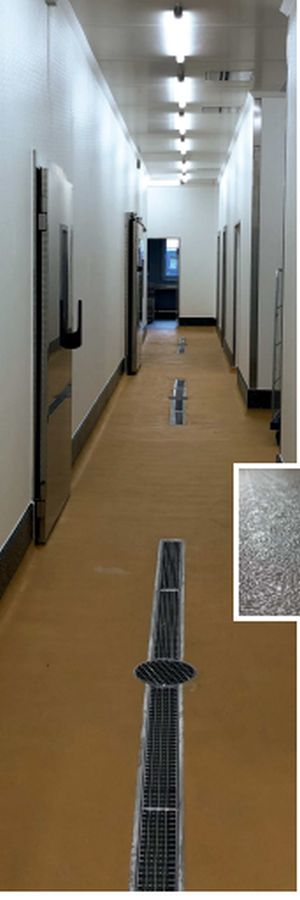

Paying attention to the crossing points of “black and white” goods as well as people is merely the basis of sound planning. Slopes, locations for unneeded smoke trolleys, floor drains and gutters as well as the associated surfaces are also part of the process. Different sections in a business also have different requirements for the floors as well as the wall surfaces. These demands drive the company from Lonnerstadt in Franconia ever further in the detail solution.

With its partner for hygienic interior finishing, Mahr Bauelemente, it now offers solutions that banish almost 100 % of “silicone joints”, commonly called soft joints. These are replaced by GRP panels to the highest hygienic standard as well as a two-component hard jointing that is

which is resistant to high-pressure cleaning and has low-maintenance properties.

PROFESSIONAL EXECUTION

Another important point is the utilisation of waste heat in technical rooms as well as in the kitchen.

Planning and realising a meat-processing plant according to the latest standards requires a look at the operating processes, the latest materials and the resources from waste air and waste heat.

This heat can, for example, support heat recovery for the use of process water, which is now standard in such operations. All the planned details and processes must, of course, be carried out correctly. The company also supports its customers in the area of construction management and supervision.

“After all, what good is good planning if it is inadequately executed?” asks

Michael Wirth, managing partner of the company. “Another

aspect of our work is 3D-realistic planning. Here the possibilities are now almost limitless. Photo-quality views and virtual tours of the respective facility are a matter of course for us.

After all, we cannot expect spatial imagination from every customer,” he adds. Clients are accompanied from the initial idea to the operational building. This ensures that the common goal can be achieved without any nasty surprises.

In summary, it can be said that operational planning for such projects is in good hands in order to have a partner with experience and ideas at one’s side.

ideas at one’s side. „We are a young, committed team with extensive experience in the above-mentioned areas. We can now look back on a large number of

references and look forward to supporting many more butchers’ shops,” emphasises Michael Wirth.

www.schwan-projektgmbh.de

Recent Comments